Pre Engineered Building

Steel Structure

Highest quality materials

Highest quality materials, expert design, and state-of-the-art manufacturing facility make our steel buildings the leader in the industry. Steel Factory Mfg prefabricated steel buildings are manufactured to meet and exceed all industry standards and all national and international building codes. Our steel building kits can be tailored for any commercial, agricultural or residential application. We custom design, engineer and manufacture complete packages. We do all the cutting, drilling, and welding at the factory for you, so on site there is only simple nut and bolt assembly. It’s that easy! Founded in 1992, APEX ENGINEERS (PVT) LTD, Pakistan. has been specializing in designing and manufacturing steel structure buildings, steel structures, Pre fab Pedestrian Bridges, container houses and section steel ever since.

Applications

APEX offers a complete line of quality steel buildings and made structures appropriate for vast variety of applications. Our different models of pre-engineered steel building kits have many applications:

- Auto Body Repair Garages

- Cold Storage

- Mini Storage

- Warehouses

- Welding Shops

- Airplane Hangars

- Prefab Container

- Control Rooms

Our steel structure products are...

- 1- Industrial Building Plant

- 2- Mobile Steel Containers

Highest Standards for Engineering and Manufacturing

Our skilled design professionals, factory employees, and distributors have become obsessed with providing only the highest quality, most durable products at the lowest prices in the industry. State of the art engineering and design allows the factory to manufacture clear span metal buildings up to 200 feet wide and in unlimited lengths. There is almost no restriction on possible building size.

Pre Fab House

The prefabricated house is economical

This product adopts the framework of light steel structure system, by using the sandwich panel as panel material and combining by the standard model machine. The steel structure components are fixed by the screw. The prefabricated house is economical in environmental protection, and can be easy to assembly and demolition, which achieved the construction concepts of common standardization for temporary building, setting environmental protection & energy saving, rapid and highly efficient building. It is widely used in the field of Large-scale exhibition, entertainment, sports, docks, industrial and civil buildings, etc, as the temporary construction building.

Prefabricated house Features:

Light steel structure is the frame of our building, which meets the design requirements of steel structure.

Standardized components make it easy to install and dismantle. It is especially suitable for emergency projects.

Because prepainted steel sheet or sandwich panel is adopted, the whole structure is handsome.

Reasonable design makes it reusable. The reusable character makes it environment friendly and economical.

First class material, reasonable price, once and for all investment, low requirements for base and short completion time make it cost efficient.

It can be relocated up to 10 times. It has 15 to 20 years

durability.

FRP Toll Booth & Projections

Fiberglass (FRP/GRP) products

Fiberglass (FRP/GRP) products offer many advantages compared to traditional materials like stainless steel, concrete, or wood. With its extreme corrosion resistance, fiberglass products are the most cost effective over a lifetime for many applications. They also provide high strength, low weight, ability to withstand high temperatures, and customization capabilities. We have supplied Toll booths for Motorways/Highway, Building Safety & Security Rooms projects in Pakistan and still about to supply more. Fiberglass composites are made up of glass fibers and resin. The resin and glass configuration are what determines the specific advantages of a fiberglass product.

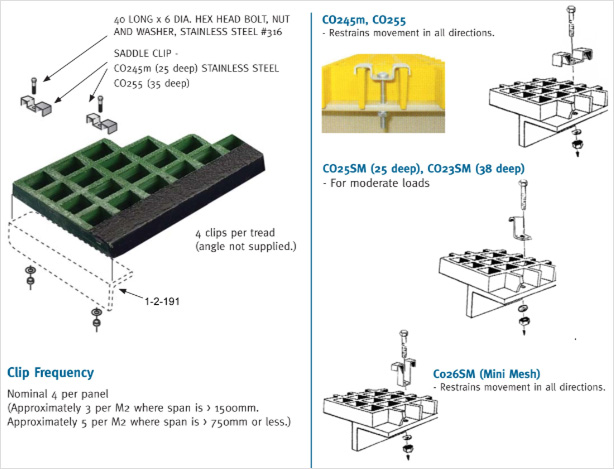

FRP Grating

What is FRP Gratings

FRP Gratings – fiberglass reinforced plastic grating – are engineered not only for high strength, but also to overcome corrosion problems found in chemical and mining industries where corrosive products are used. APEX FRP grating is designed to provide the ultimate in reliable performance even in the most demanding conditions. APEX FRP Grating is the natural choice for quality and price. APEX FRP grating is a molded, one-piece fiberglass reinforced plastic grating, available in standard panels or custom panels made to order from drawings supplied. It is principally used for floors, platforms, stair treads, ramps and trench covers. APEX FRP grating is composed of 65% resin and 35% continuous fiberglass strand. The Panel is 3660 mm x 1220 mm.

Features

Corrosion Resistance

Whether the grating is exposed to continuious submersion, splash, spills, fumes or gases, the high resin content of FRP resists corrosion to a wide range of chemicals.

Fire Resistance

Flame spread rating of class 1, 25 or less, in accordance with the American Society for Testing and Materials (ASTM) E-84 tunnel test method.

Easy on-site Fabrication

Standard FRP grating panels are ideal for in site fabrication. It is easy to cut with standard cutting tools to suit individual installation. Sealing kits can be provided to seal cut edges.

Cost Performance

FRP has a long life span with low installation costs.

Light Weight

FRP grating panels are light weight, they can be easily handled without means of mechanical hoists or lifts.

Two Dimensional load bearing

Squared pattern moulded grating offers load bearing capacity in both directions.

Non-Sparking

Ideally suited for installations where combustible gases may be present. FRP will not cause sparking when impacted by metallic objects.

Non-Electrically Conductive

FRP is not electrically conductive. This makes it ideal for work platporms, flooring and fencing in electrically hazadous areas.

Optional Anti-Slip Surface

An anti-slip surface can be provided by embedding a coarse gift into the resin.